- Details

- Category: Blog

Organisations that achieve year on year improvement in Overall Equipment Effectiveness (OEE) use it as a "Leading rather than Lagging" Indicator.

This approach when combined with the OEE Focussed Improvement toolbox creates an improvement Glide Path to guide progress towards industry leading levels of performance.

Comparing the impact of improvement ideas against the improvement glide path predictions provides a measure progress of actions to improve:

- How the equipment is prepared for production,

- How well it performs when running

- The quality of process output

From our work with well respected and award winning organisations, four sets of improvement glide paths link together to provide a road map to industry leading performance. These are:

- Breaking out of reactive

- Scaling up for growth

- Reducing short stops and Quality Defects

- Delivering Step out performance.

OEE as A Leading Indicator

To use OEE as a leading indicator, set quarterly improvement targets to reduce specific hidden loss areas. Refer to the above glide paths for details of Focussed Improvement tactics to apply. At the beginning of the quarterly cycle mobilise the team to add detail to the target, apply the steps of the Asset Improvement plan including the creation of a trouble map and improvement glide path.

Follow up actions daily as part of the daily management routine but track progress against the glide path using a weekly rather than daily OEE review cadence.

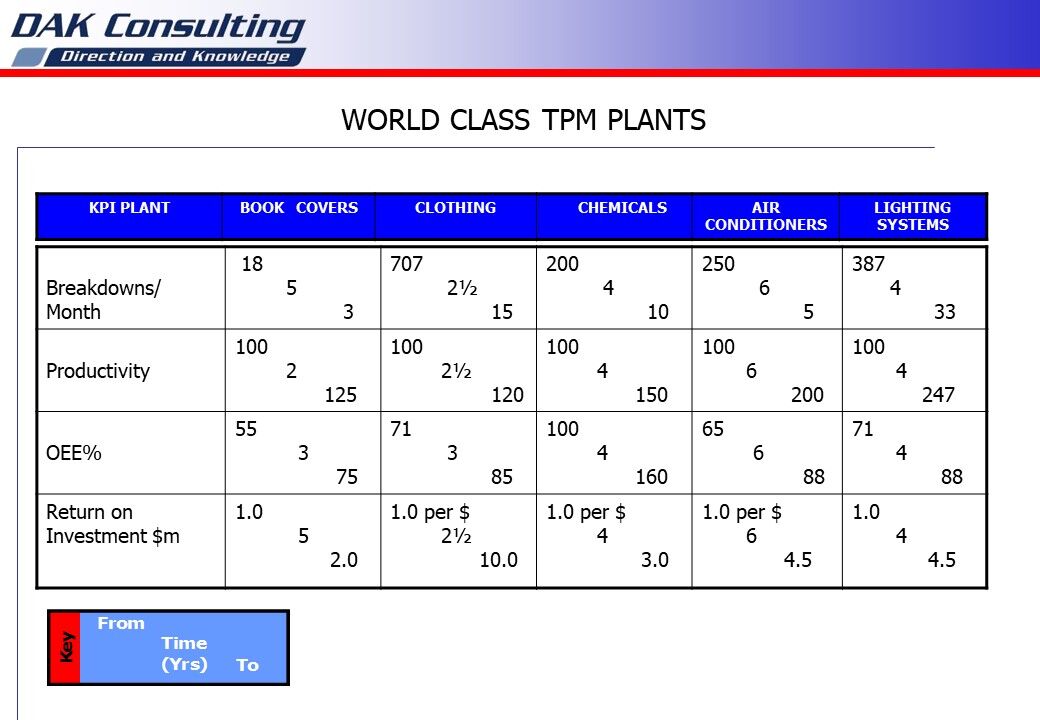

By using OEE in this way, high performing organisations are able to achieve increases of 30% to 50% in OEE over a 3 to 5-year period (Figure 1)

Figure 1 TPM Case Study Results By Industry

The business benefits are significant and include,

- Increased capacity at low or no cost

- Improved delivery performance

- Shorter production lead times

- Reduced material, energy and labour costs

- Improved quality consistency and reduced scrap.

In addition to these gains, Front line teams develop a deeper knowledge about their work environment and focus on improvement as part of their day job without having to be told to do so.

In summary.

- Overall Equipment Effectiveness measures how well you achieved what you set out to do.

- OEE Focussed improvement toolkits set out tactics to systematically deliver the full potential of the equipment

- That provides an improvement glide path to track progress and guide next steps as part of the Performance Management process.

For more information access of free resources, use the contact form, email info:@dakconsulting.co.uk or call us on +441491 845504.