We help organisations to develop the skills and processes to deliver year on year performance gains.

At the heart of our support is the application of Lean and Total Productive Manufacturing principles and techniques to generate improvement pull from shop floor teams.

TPM provides the roadmap to develop the capability to achieve zero breakdowns and no touch production. Lean thinking provides the insight to drive out waste, improve workflow and remove non added value activities.

Developing Improvement leaders

The content of our programmes are designed to develop the capability of improvement leaders at all levels. That includes:

- Senior Managers.

- Front Line Leaders.

- Planners.

- CI Managers and change agents.

- Project Teams and business sponsors.

- Support personnel.

Short Courses About Improvement Best Practices

The content of our training courses, learning clubs and support plans are based on our work with well known and award winning organisations helping them to apply Lean and TPM principles to deliver year on year performance gains. That covers

Taming Technology by establishing basic asset conditions and sustaining it through

- Asset Care best practice.

- Work standardisation and visual management.

- Effective Maintenance Planning.

Ratchet Up Performance: through the application of Focused Improvement best practices to:

- Deliver zero breakdowns and release specialist time for higher value activities.

- Define a practical OEE improvement glide path and applying those freed up resources to progress along it as part of the day to day routine.

- Develop team and team leader skills to support high performance teamwork.

Deliver Better Projects Faster : through Manufacturing Project Management best practices for:

- Project Governance

- Project Leadership

- Project Team Delivery

Embrace Advanced Technology by incorporating digitisation solutions as part of the improvement programme through best practices for:

- Identifying legacy system weaknesses and opportunities for digitisation gains.

- Designing the digitisation road map

- "Use case" evaluation and implementation

In House Training Programmes and Academies

We create training programmes and in-house training academies to drive tangible performance improvement. Programmes that will:

- Encourage ownership of learning goals and pathways.

- Provide individuals and teams with the skills they need to deliver year on year improvement.

- Reinforce a proactive culture and the values of the organisation.

All programmes have a practical workplace learning focus supported by coaching to unlock the potential of individuals and support the delivery of business goals.

The aim is to ensure that every individual feels valued and supported in their learning journey.

Support for Implementation

The content of our training courses, learning clubs and support plans are based on our work with well known and award winning organisations helping them to apply Lean and TPM principles to deliver year on year performance gains. That covers

LeanTPM Transitions 1 and 2 Improving Reliability and Resilience

- Asset Care best practice

- Work routine design and skill development

- Maintenance Planning

LeanTPM Transitions 3 and 4 Ratchet Up Performance

- Overall Equipment Effectiveness

- TPM Leadership Best Practice

- Daily Management and Front line leadership

- Specification and Life Cycle Cost Management

- Design and Performance Management

- Project and Risk Management

Workplace Learning

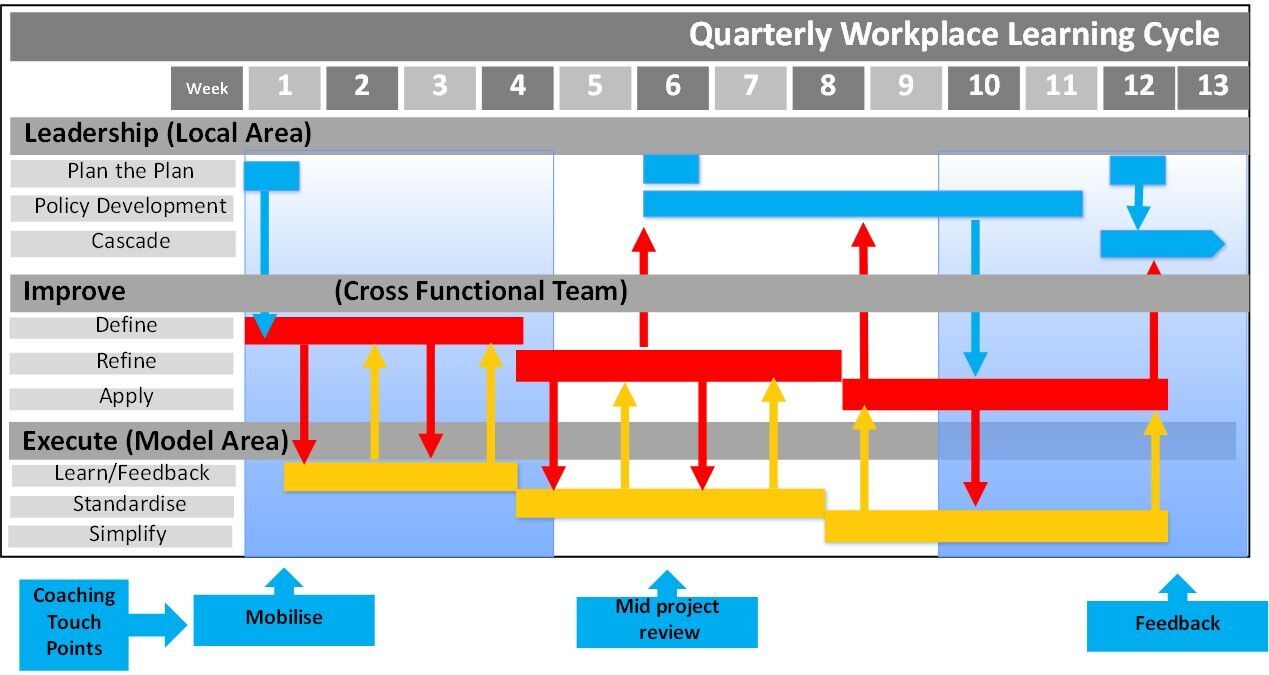

Each course includes activities to define a bespoke road map for applying lessons learned to the workplace build around 90 day workplace learning cycles. That sets out how to apply coaching plans, capture lessons learned and facilitate engagement. This also provides a cadence for change management and high performance teamwork development.

Support for Change Management

As shown in the above graphic the quarterly workplace learning cycles provide coaching touch points to guide progress and reinforce change management direction as part of the day to day management.

- The first touchpoint is used to confirm that improvement areas are identified, prioritised and action plans are realistic and achievable,

- The second touchpoint is used to confirm that the improvement team has been mobilised and they are tracking the impact of their programme;

- The final touchpoint is used to confirm benefit delivery and support formal recognition of success.

Using these we can work provide support for internal improvement leaders to:

- Raise awareness, win hearts and minds and get buy in to those new ideas.

- Improve insight into issue/opportunity causal factors and identify next steps.

- Surface barriers (real and imagined) overcome problems, refine ideas and progress them further.

- Guide the introduction of new working practices.

Use this link to find out more about our Courses, Support plans or to Contact us to discuss how we can help your organisation to deliver its improvement potential.