- Details

- Category: Blog

Effectiveness is a measure of how well a process achieves its purpose, a measure of how often that process hits that "right first time" sweet spot. The gap between the Effectiveness achieved and 100% is a measure of the health of the process.

Although the most widely used measure of effectiveness is OEE (Overall Equipment Effectiveness), Effectiveness can be applied to improve any process including Maintenance Management.

So what?

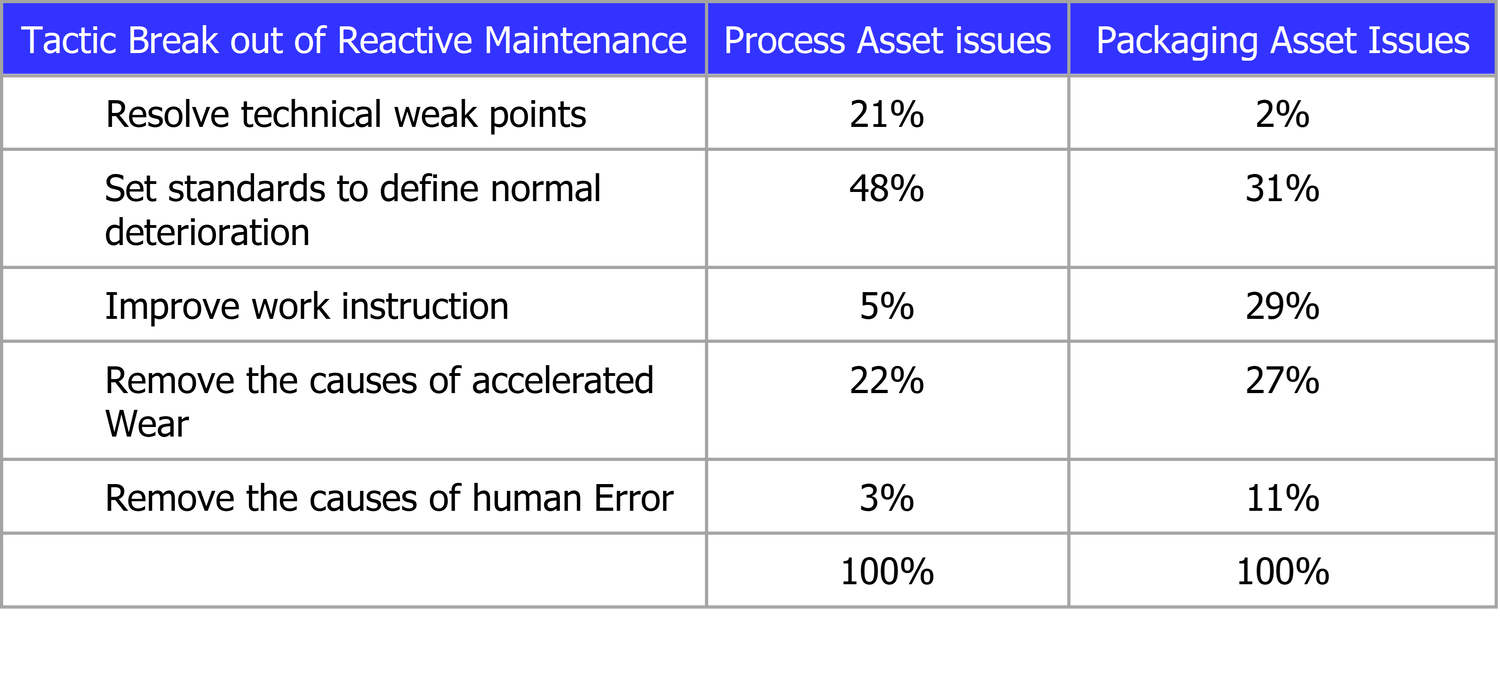

Maintenance is most effective when engineers time is directed towards getting the most out of the asset. The table below contains the results from a food processing and packaging plant on their journey from over 80% of time spent on reactive maintenance to less than 10%. This shows the countermeasures used to break out of reactive and what % of issues each type of countermeasure resolved. For example countermeasures to 48% to reactive maintenance of process assets, involved setting standards to be able to consistently identify deterioration levels and trigger actions to restore condition before failure occurred.

The biggest barrier to overcome, was a lack of robust inspection standards to trigger actions to restore component condition prior to breakdown. Accelerated wear (cleanliness) comes next. In other words, reactive maintenance is a characteristic of weak management processes. Get this right and time is released to deal with the remaining issues.

Measuring Maintenance Effectiveness

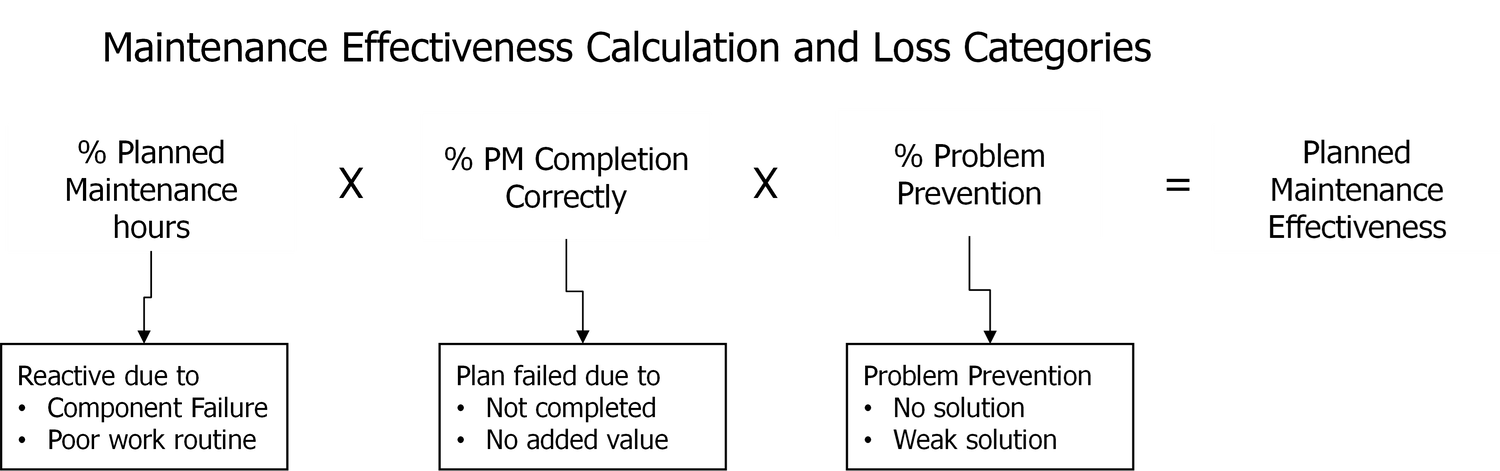

Maintenance Effectiveness provides a measure of how well resources are used and the improvement glide path towads zero breakdowns. This uses 3 factors as set out below.

Priority losses categories can then be targeted using the classic Plan Do Study Act cycle credited with transforming Japanese Manufacturing Industry from third rate to world leading by driving progress towards “right first time” outcomes.

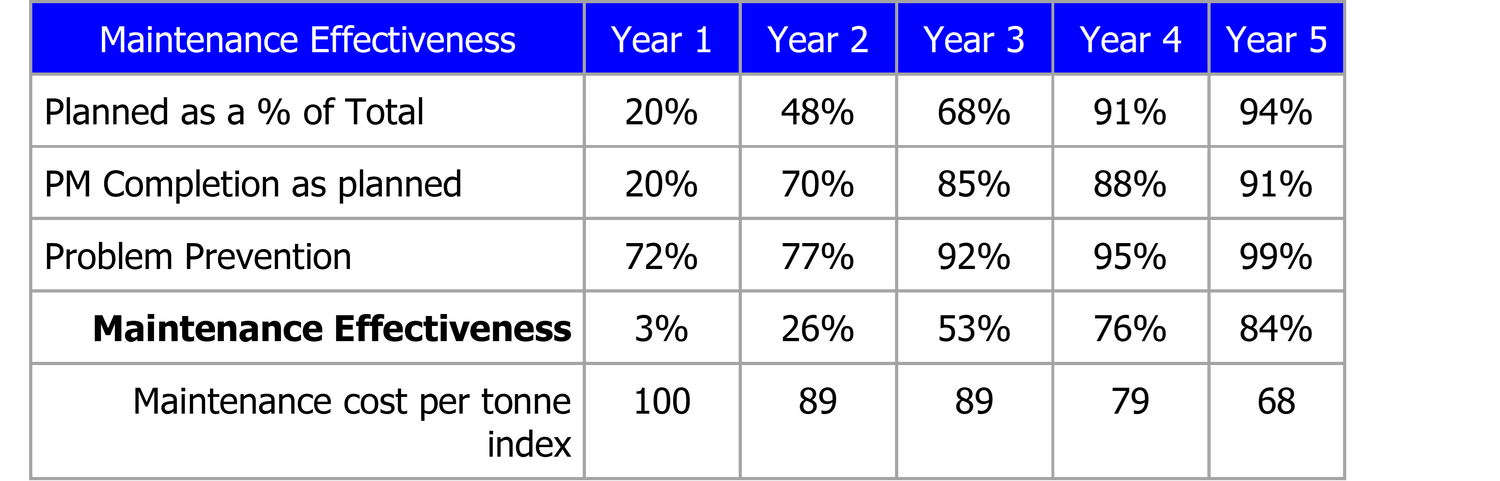

The Effectiveness glide path for the food processor from table 1 is shown below. This illustrates how, as effectiveness improved and around 40% of engineer time was released, it was redirected to improve the problem prevention score from 72% to 99%. The outcome of improved Maintenance Effectiveness included a reduced maintenance cost per tonne to almost 2/3rd of previous levels.

Moving Beyond Zero Breakdowns

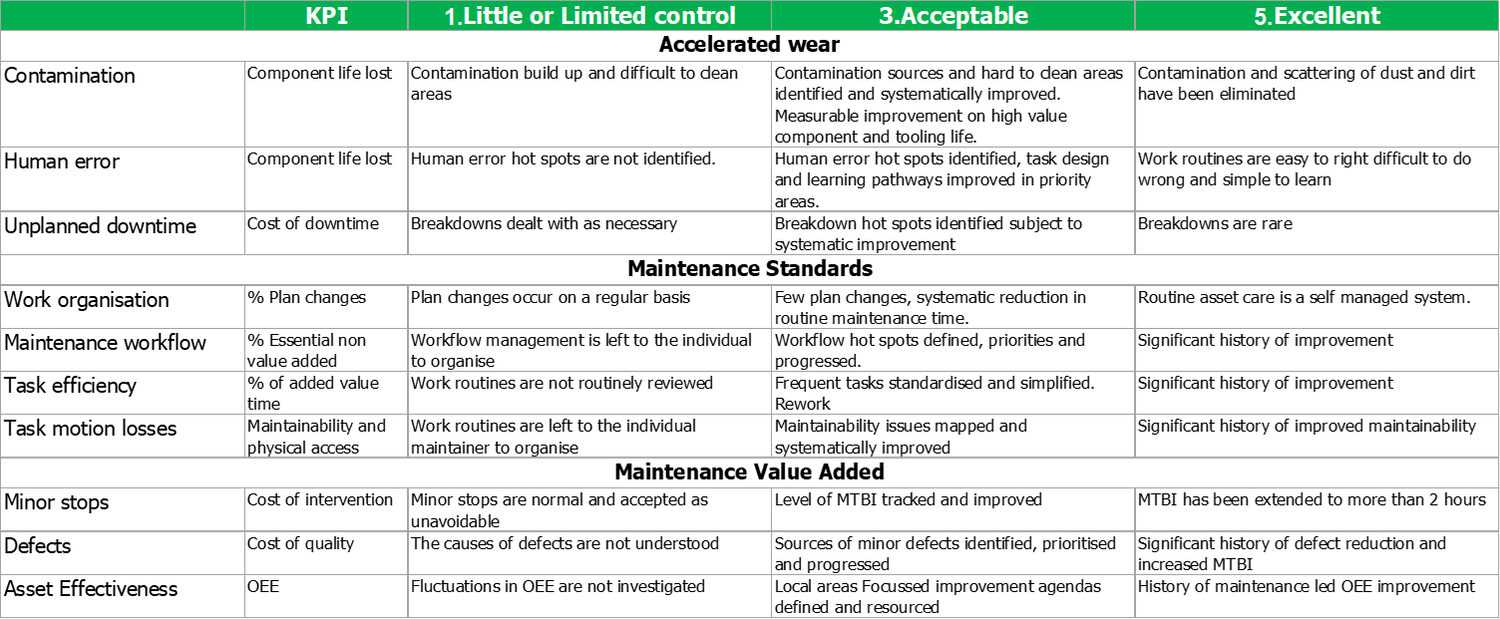

An important TPM concept underpinning the use of Effectiveness is Loss Tree analysis. This provides a set of improvement glide paths that drive effectiveness up and cost down. The table below summarises the loss tree steps for the case study.

The first order priority was to work on the causes of accelerated wear whilst locking in the gains by improving Maintenance Standards. This dealt with around 70% of recurring failures.

As breakdowns became less common, the focus moved on to improving maintenance value added. The outcome was to extend MTBI (Mean Time Between Intervention) which extended component life (reducing maintenance material cost) and the risk of human error. The most important improvement, however, was the transformation of Engineer mindset from fixing breakdowns faster to finding ways of adding more value. Priceless!