- Details

- Category: Blog

If the roadmap to industry leading performance was simple, everyone would use it but less than 1% of organisations that embark on that journey stay the course. A recent survey provides some insight as to why that is the case.

The research assessed organisational approaches to improvements and found that:

- The least successful organisations were those who allocated resources to deal with issues as they arose or worked on technology projects based on what their competitors were doing. In these organisations, the main focus was on sustaining the current level of performance. The trigger for action was driven by a desire to avoid short term performance pain.

- Leaders in the most successful organisations adopted an approach where every role was actively engaged in delivering targeted improvement goals to secure the full potential of the operation. The trigger for action was driven by a desire to achieve a medium to long term business vision or outcome.

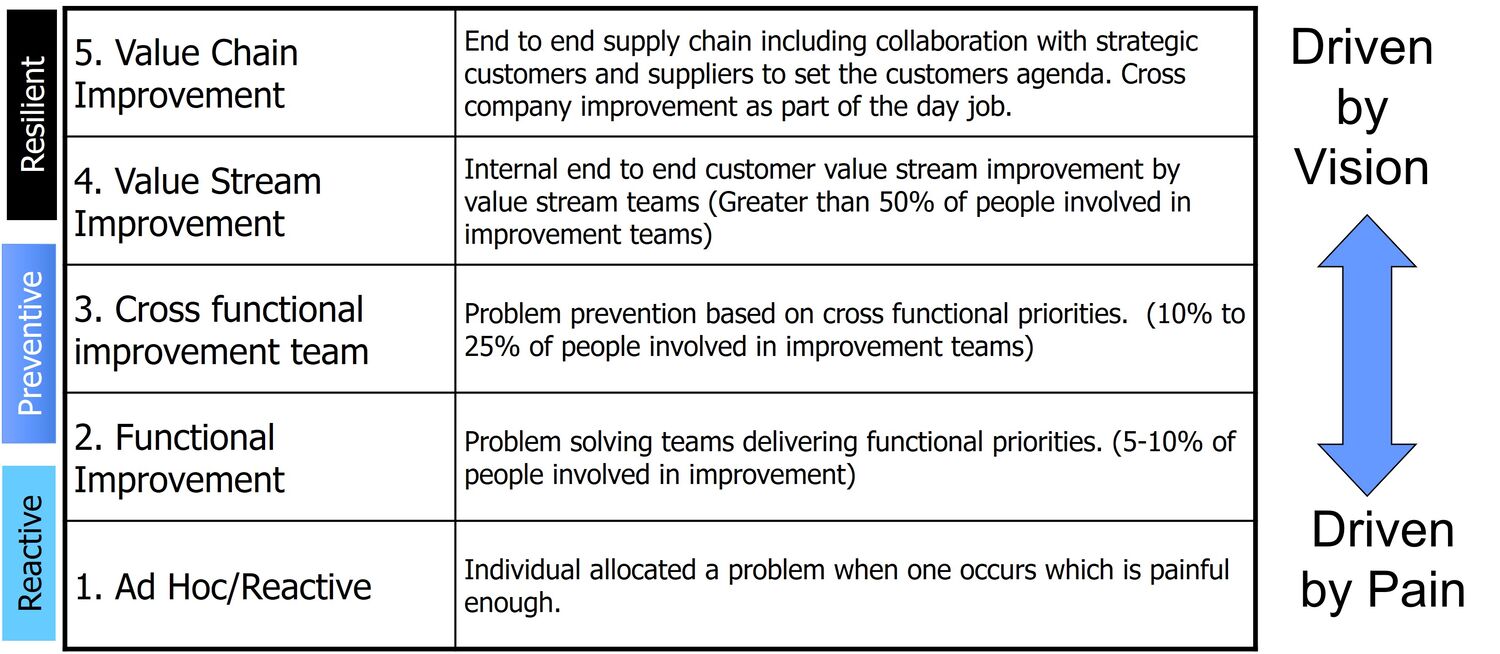

The table below summarises 5 sets of action triggers that describe the continuum of outlooks from least successful (1) to most successful (5).

Table1 Organisational Approaches to Performance Improvement

The research highlights three main drivers of successful improvement in organisations scoring 3 and above on the above scale. They are:

- Set the improvement agenda to deliver longer term business goals. That keeps the pressure on improvement as part of the routine.

- Less successful organisations tend to deal with issues as they arise and ease off when things are more or less on an even keel. They then have to make up ground

- Align cross functional improvement goals and priorities to deliver those goals.

- Functions within less successful organisations, pursue separate improvement agendas which can inhibit collective progress.

- Invest time and resources in developing a richer insight into cause/effect to remove barriers to improvement by refining ideas through practical application.

- Less successful organisations miss out on the opportunity to share ideas, enhance problem ownership and develop skills to test out and refine ideas as part of the day job.

A Case Study

All of the industry leading performers had a history of improvement beginning with a historical struggle to achieve and sustain their success.

A great example of the application of these research findings is Toyota. Although an industry leading organisation today, they struggled at the beginning of their improvement journey. One of the reasons for their success was the identification back on 1947 that:

"Toyota needed to catch up with USA levels of productivity which they estimated was a 9 fold increase from current levels."

A big ask. Not just because of the technical challenges involved as the following quotation reveals.

"At that time, Resistance from the production field was naturally strong"

So at the start of their journey they had to overcome resistance to change. They did that by using practical projects to help those production personnel to develop new insights and engage them with delivering the business improvement goal.

"By actually trying, various problems became known for example sometimes there were so many adjustments that those doing the job found it difficult to handle"

The practical projects surfaced barriers to progress and by working on those issues they were able to develop the capability to quickly identify and resolve other problems.

Moving Beyond Problem Solving

In theory, this sounds a lot like problem solving but problem solving methodologies are designed to deal with problems. To build on good practices involves reflecting on what has worked well and what didn't to learn lessons about how to achieve more in the future.

That widens the range of factors that can be considered to include enablers such as education and training, workplace design, use of technology, and capital investment.

Without that wider perspective, the best you can hope for is that results for next year are no worse that they were last year.

"If you always do what you’ve always done you will always get what you’ve always got." Henry Ford

Changes in things such as customer expectations, product range, technology or legislation drives the need to adapt. What industry leading organisations recognise is that the improvement process is a powerful vehicle to do that.

How DAK Academy Can Help

Our support plans are designed to deliver practical gains over bite sized 3 month/90 day improvement cycles covering:

A. Planning the Plan Diagnostic sessions to set out foundation concepts and support an assessment of current status. Outputs include action plans, issue prioritisation and targeting to apply lessons learned.

B. Creating a Centre of Excellence to identify the detailed trouble map and begin practical steps to deal with gaps and barriers to progress during the next 90 day improvement cycle.

C. Implementation Coaching and guidance to develop skills, lock in the gains and transfer lessons learned.

The content of support plans is defined to suit the needs of the improvement challenge, the current status of the organisation and capabilities of those involved. Below is an example of a DAK Academy support pan to scale up output and progress towards industry leading performance levels.